AI-enhanced Vision Applications

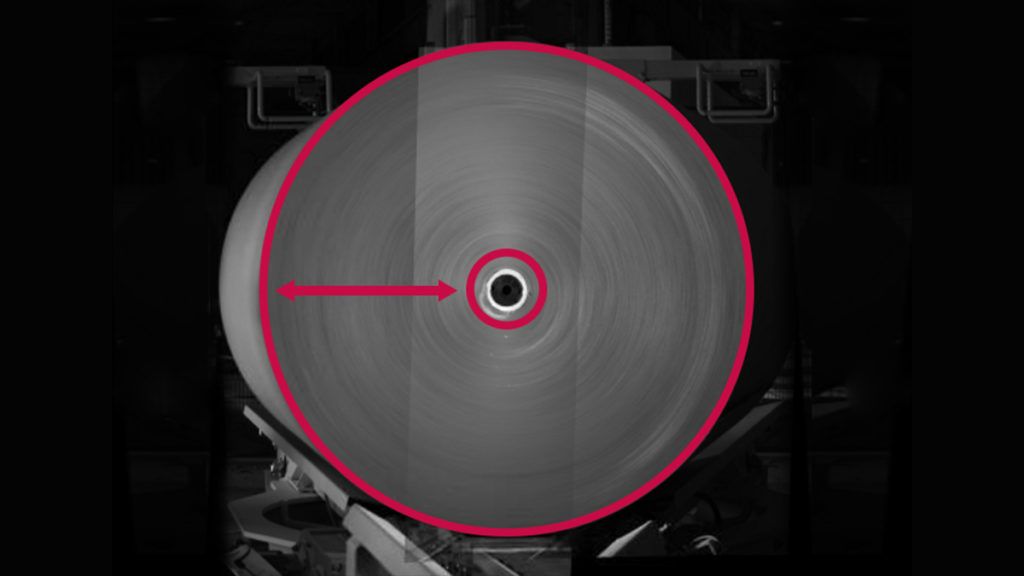

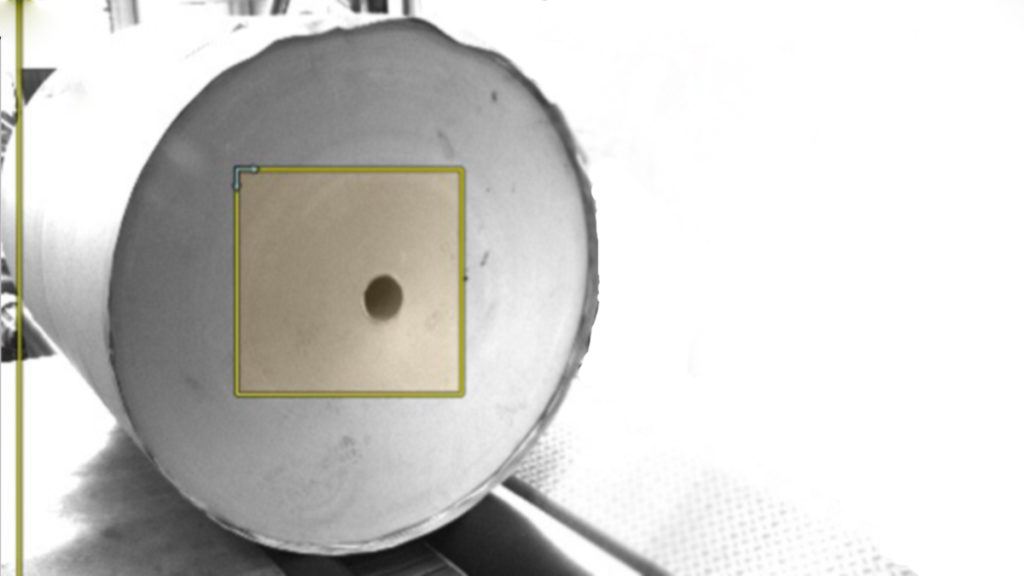

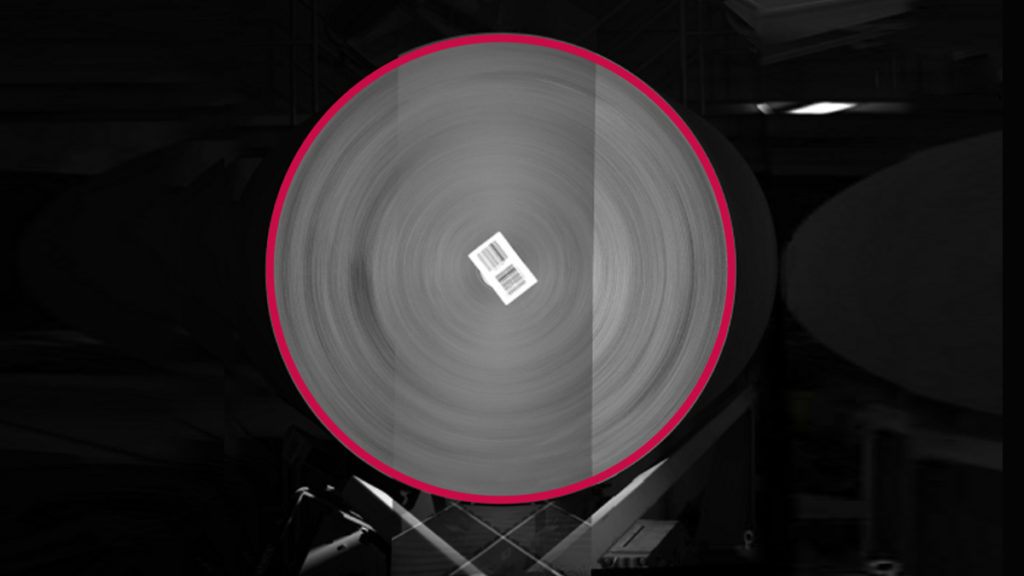

A comprehensive range of AI-enhanced analysis applications take web inspection and web monitoring to a completely new level. They improve production flow and product quality, manufacturing efficiency and operator safety.

Applications – Paper & Board Industry

Applications – Pulp Industry

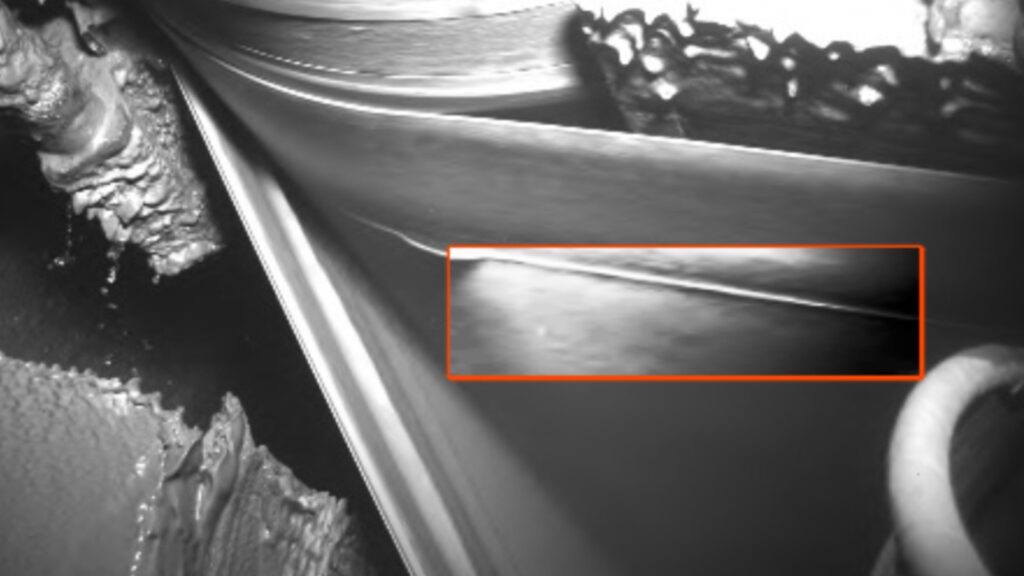

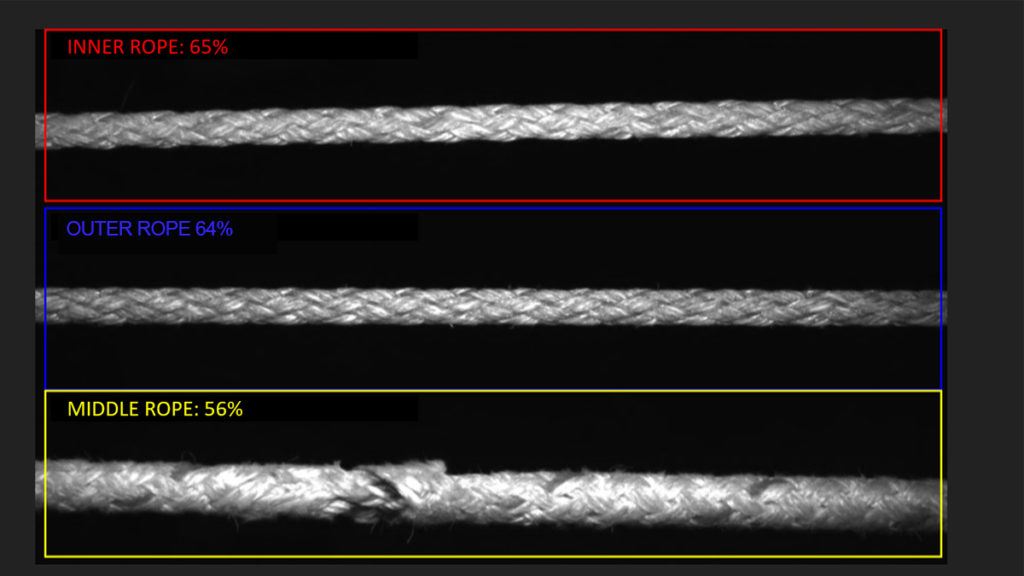

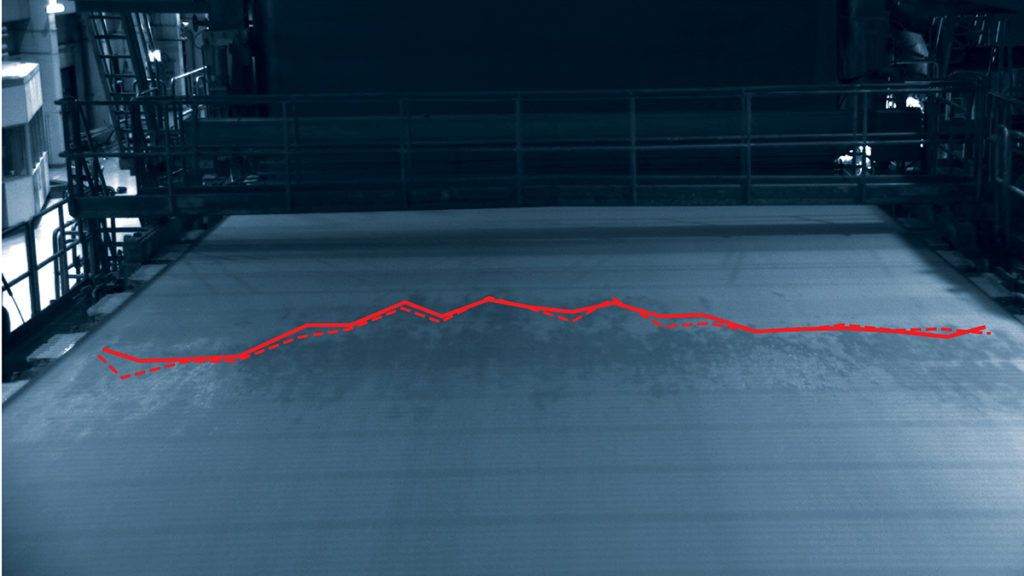

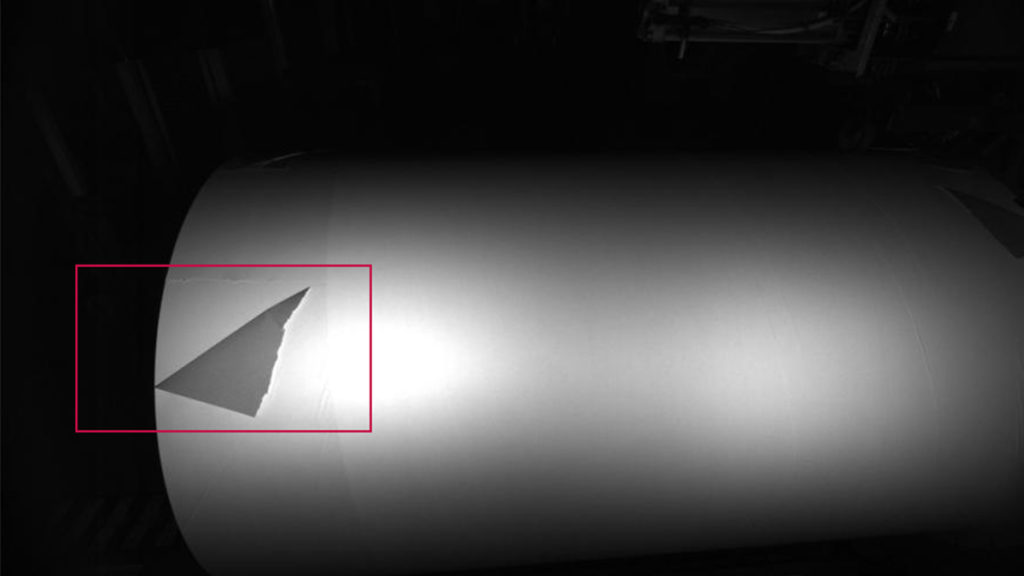

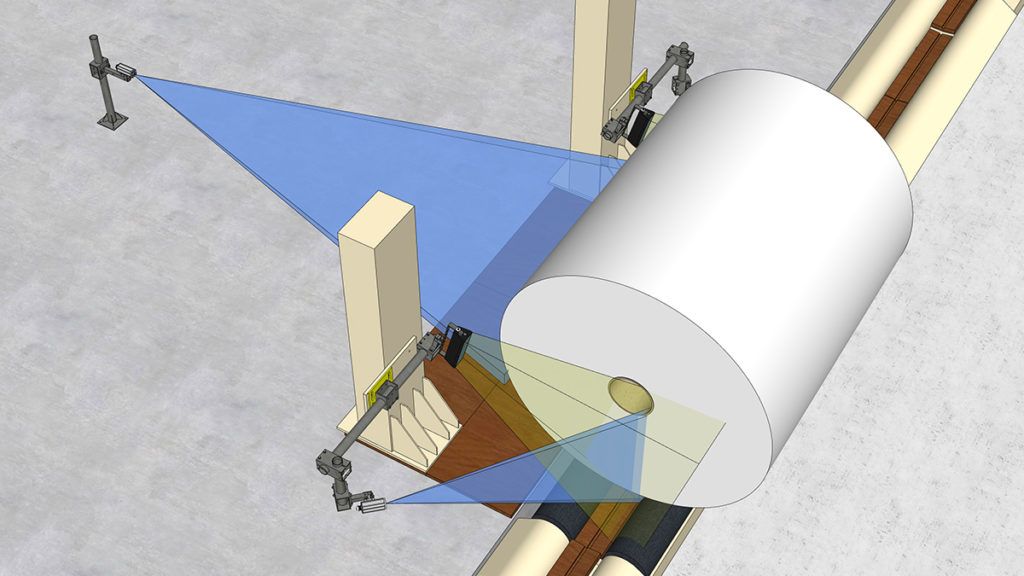

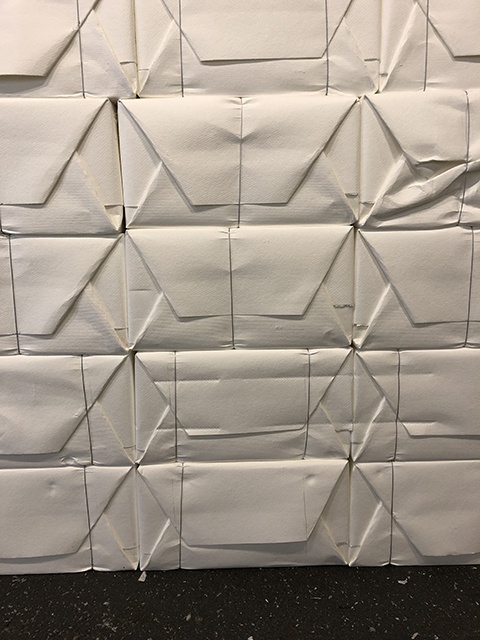

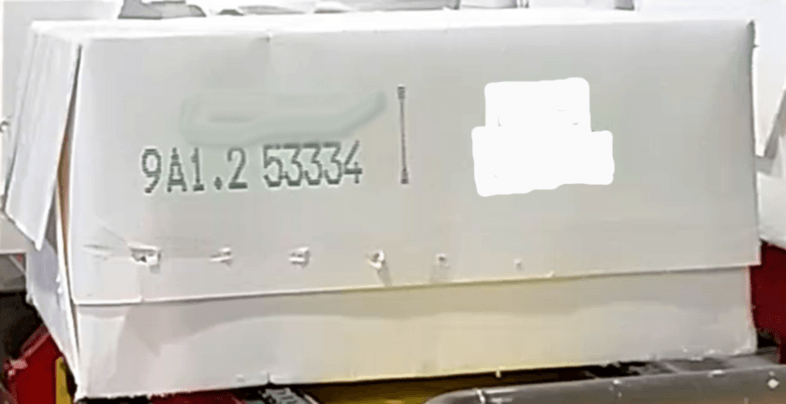

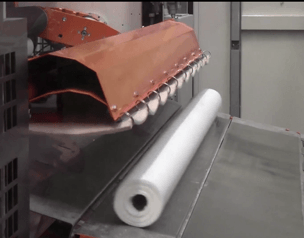

Applications – Tissue and Converting

Procemex OnePlatform Converting Tools reveal process and quality problems that cause breaks in converting. The Tools cover known key process locations.