Automatic Threading Rope Monitoring

The Automatic Threading Rope Monitoring examines the condition of threading ropes and their expected lifetime 24/7. The Automatic rope condition monitoring prevents serious damages and expensive unplanned production shutdowns.

Significant cost savings

- Broken threading ropes cause expensive paper machine down time

- Installing a new rope requires shutting down the paper machine

- Threading a new rope through the machine without the old rope can take 12 to 24 hours depending on the damages

- Annual total cost caused by rope breaks can be > 0,5 M €

- Automatic Threading Rope Monitoring enables rope changes as preventive maintenance during scheduled down time

- Rope breaks are a safety hazard. They can cause severe damage to people and equipment.

Rope Condition Monitored 24/7

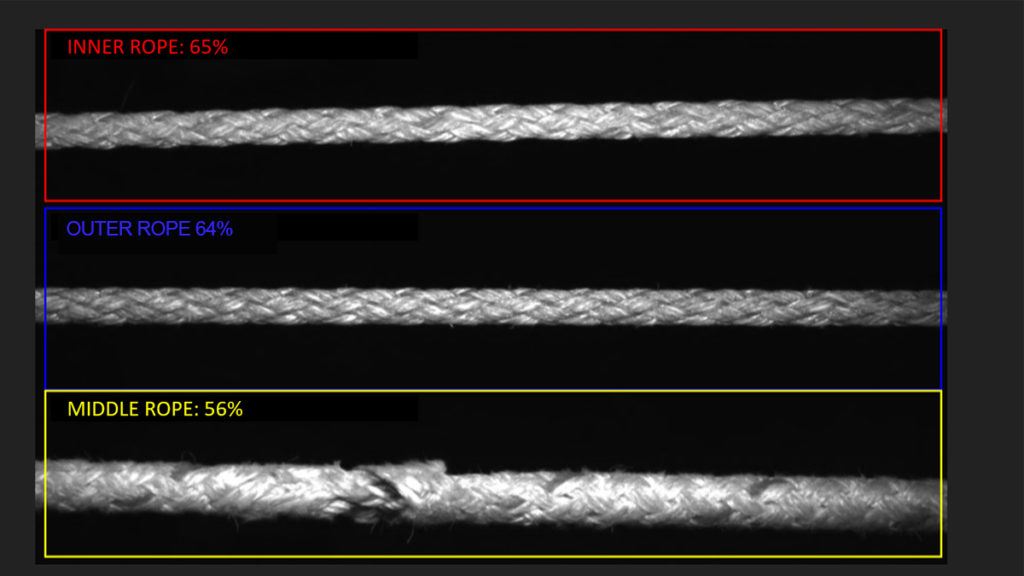

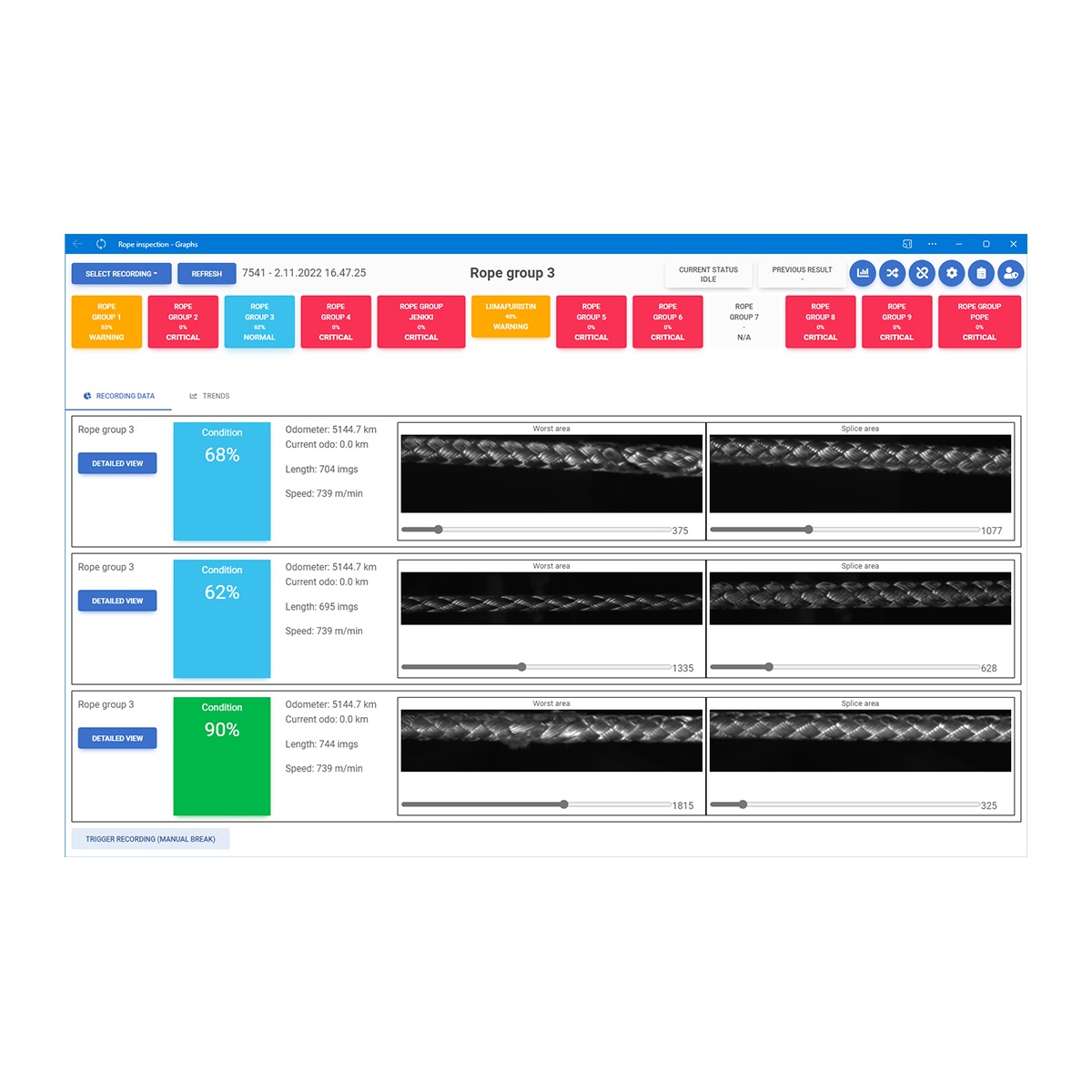

- Monitors threading rope’s condition and expected lifetime 24/7

- Increases the mill safety

- Helps to prevent:

- Unexpected rope & web breaks

- Unplanned machine shutdowns

- Optimizes threading rope change intervals

- Saves operators’ time

Success Stories

Success story

Metsä Board Äänekoski, Finland monitors Carrier Rope Condition 24/7

The latest functionality adopted by Metsä Board Äänekoski, Finald has been the Tail Threading Rope Condition Monitoring. The carrier ropes’ condition is continuously monitored with Procemex cameras utilizing cutting-edge AI-analysis technology. As a result, the threading rope changes can be conducted as preventive maintenance during scheduled machine shutdowns, reducing the number of unexpected and expensive web breaks and machine down times.

Nippon Dynawave Packaging increases superior product quality with Procemex Web Inspection solution

BillerudKorsnäs Gruvön Mill: “We Are Really Happy to Run Procemex OnePlatform System”

Metsä Board Äänekoski: Higher Customer Satisfaction and Line Efficiency with Procemex Web Monitoring and Inspection System