Keeping Quality Consistent: How Long-Term Service Contracts Build Trust and Performance

When web inspection and web monitoring systems have been running for over a decade in a demanding paper mill environment, reliability is no coincidence. It’s a result of smart choices, consistent maintenance, and mutual trust between the supplier and the customer.

A Track Record of Trust and Results

At DS Smith’s Kemsley mill, Procemex systems have been operational since 2013 on PM 3, PM 4, and PM 6. All three paper machines are equipped with Procemex OnePlatform, where Web Monitoring and Web Inspection work seamlessly as one system. PM3 already uses Procemex’s modern Crystal Smart Cameras with 12 MP resolution, while other machines are also being upgraded with new smart cameras equipped with ProClean pinhole technology and new Eco Spot lights.

The recent renewal of their 3-year service agreement is a clear sign of trust. “It means we’re satisfied. Otherwise, we wouldn’t keep going,” DS Smith’s Automation Systems Engineer Phil Ames declares.

Predictive Service keeps the System like New

Thanks to the pre-scheduled service visits and ongoing expert support, the Procemex OnePlatform system remains as good as when it was first installed. Camera cleanliness, often a challenge in paper mills, has been effectively managed through ProClean technology, which keeps pinhole lenses clean longer and ensures consistent high image quality.

“ProClean pinhole cameras stay clean much longer. While cleaning is sometimes necessary, the difference is clear — we get consistently good images,” Andy Devlin, DS Smith’s Automation Engineer says, highlighting the importance of camera performance reliability.

Many of the system upgrades, such as new servers and additional Winder cameras, have been the result of ongoing discussions and expert recommendations made during these regular service visits.

Beyond hardware upkeep, Procemex service stands out for its professional and human support. Problems are solved quickly. And not just fixed, but followed through to ensure the issue is truly resolved. “They don’t just tick a box,” Phil Ames notes. “They care. They check back. And when we call, it’s a real person, not a chatbot. The attitude is spot on.” Phil Ames reflects on his experiences.

Better Daily Use Through Training and Tips

Regular service check-ins include operator training and expert tips that improve system use. Procemex service experts know the system inside out, and are capable of providing detailed advice that helps to harness the full potential of the OnePlatform system. “Both the operations team and engineers have become more confident and efficient. Ownership and understanding have grown, leading to fewer unnecessary support calls and faster responses.” Phil Ames reflects.

Trust Built on Teamwork and Support

Beyond equipment maintenance, the service agreement fosters a partnership based on trust and collaboration. “It’s about working together towards shared goals. Without teamwork, you won’t get anywhere,” Phil Ames explains.

One example of that trust happened some years back, when a new component was required after installation. Shortly after they were notified, the Procemex support team shipped the replacement part before a purchase order had been raised, trusting that this would follow. That decision ensured that DS Smith received the part as fast as possible and avoided any downtime.

Communication has also been open and transparent, even when facing challenges. “We’ve been able to talk about problems directly and work together on solutions,” Phil Ames explains. The cooperation has been symbiotic, mutually beneficial, and built on honesty, responsiveness, and shared goals.

Predictive Maintenance and Incremental Upgrades

While exact savings can be hard to quantify, the service agreement’s value is evident in reduced downtime and incremental improvements. New ProClean lenses and better cameras have enhanced image quality and defect detection, enabling earlier issue detection and fewer web breaks.

“I know the importance, because if the cameras aren’t working, we are facing real issues. We need these cameras to work. And so, I know that it’s worth it,” Phil Ames summarizes his thoughts on the importance of regularly maintained systems.

Backward Compatibility Saves Time and Effort

Maintaining backward compatibility across camera models and lenses allows upgrades to happen stepwise, avoiding full replacements. “If you stop moving forwards, you are going backwards,” says Andy Devlin, summing up the importance of system compatibility.

Because the Procemex OnePlatform system is designed to be future-proof and fully compatible, capabilities can be enhanced gradually across different parts of the system. This makes it possible to introduce new functionalities that improve defect detection, final product quality, and overall operational efficiency without needing to start from scratch.

Just as importantly, when software updates are installed, the logic and structure of the user interface stay consistent. This means there is no steep learning curve or disruption when implementing new features. “It allows us to focus on our core task, making paper, instead of spending time figuring out how to use the system again,” Phil Ames explains.

The Biggest Value: Maintaining Optimal Performance and Peace of Mind

The service agreement maintains equipment performance at a consistent level, as was the system on the date of installation. Regular reports and quick engineer responses provide peace of mind, ensuring the system operates reliably day after day.

This is especially important because the system is mission-critical. The images it produces must be clear and sharp, so that operators can make informed decisions about what caused a web break or identify the root cause of defects on the paper web. A well-maintained system is one you can rely on. It delivers continuous value and payback, day in and day out.

You might also be interested in these topics

Success Story: Metsä Board Äänekoski

Higher Customer Satisfaction and Line Efficiency with Procemex Web Monitoring and Inspection System

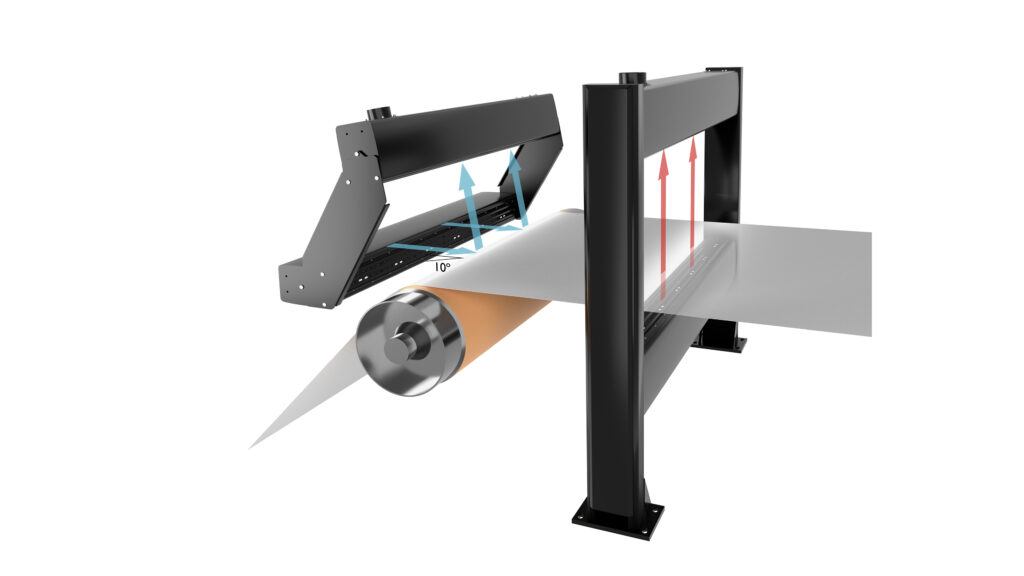

Measurement Geometries

Procemex has developed a variety of measurement geometries for detecting and inspecting different types of paper defects.

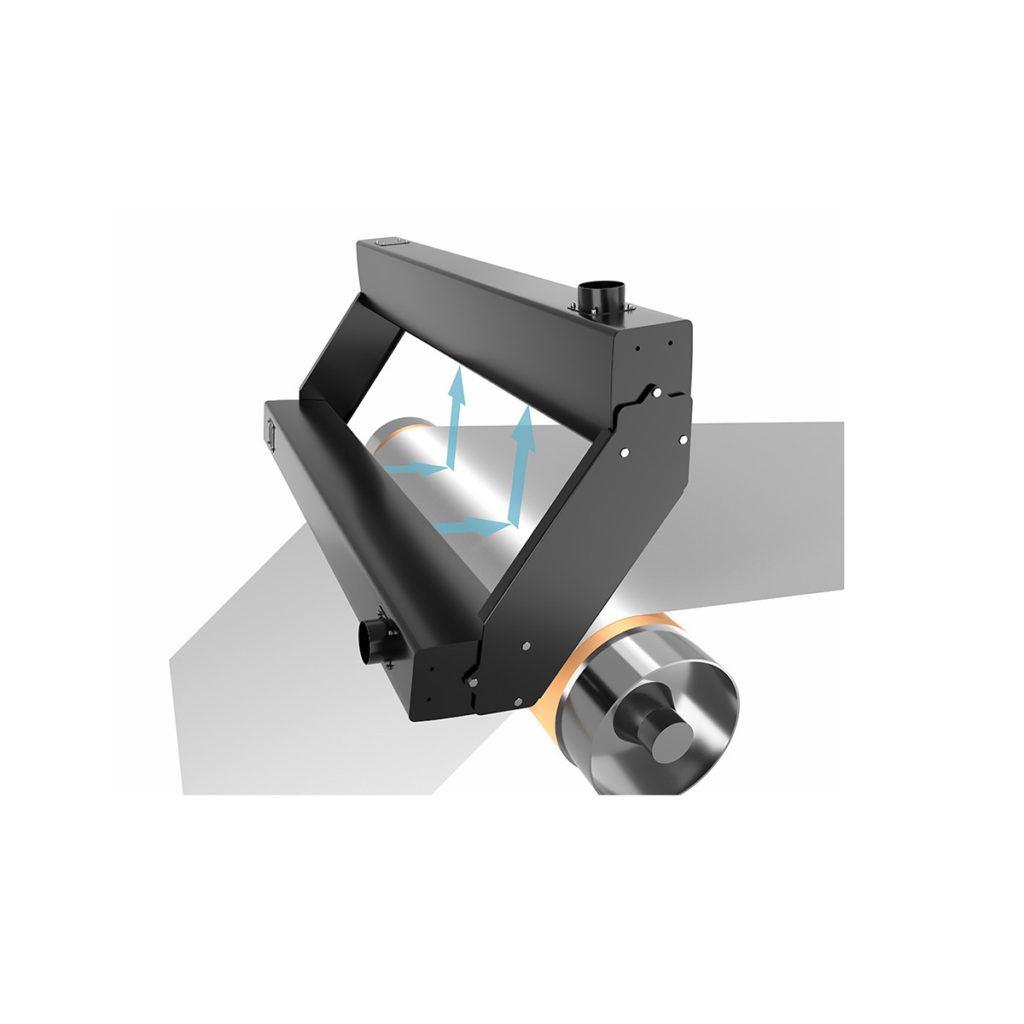

ProClean Pinhole Camera

Procemex ProClean Pinhole Cameras stay clean even in the harshest conditions