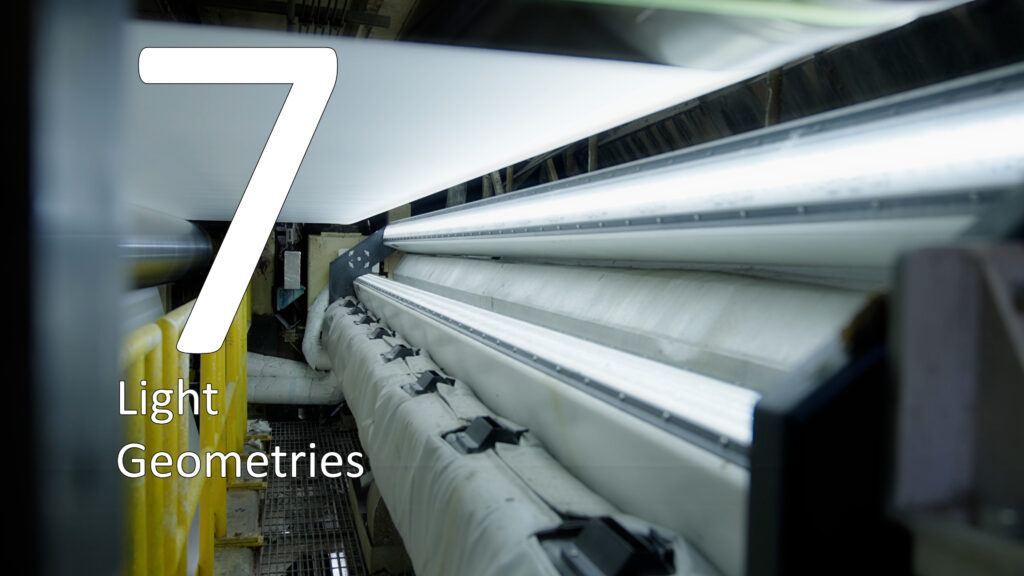

Boosting Folding Box Board quality with Multiple Web Inspection Geometries

In paper and board manufacturing, Web Inspection Systems (WIS) are essential tools for quality control. One of the key strategies to improve the detection range and classification accuracy of defects is to use multiple measurement geometries simultaneously. This approach is especially effective with high-end grades such as liquid packaging board or folding box board.

Comprehensive Quality Control for Demanding Grades

For producers of liquid packaging board, quality requirements are exceptionally high. To meet these standards, inspection systems are typically configured with several detection geometries, each designed to reveal different types of defects.

A typical multi-geometry system may include

From the top side of the web:

- UV-light detection: Reveals defects not visible in standard lighting. Especially useful for spotting oil residuals.

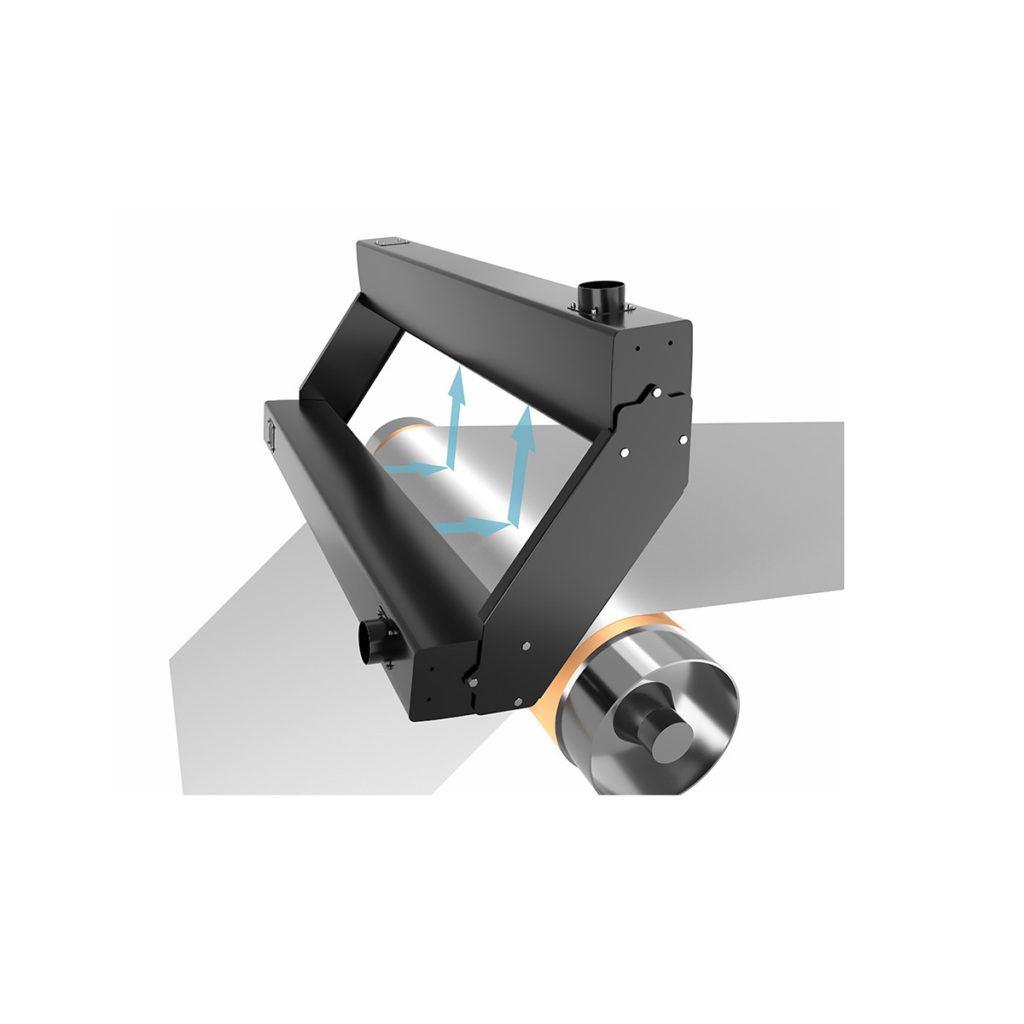

- Transmission Web Inspection: With the light source beneath the web and camera above, this setup is ideal for detecting defects located in different layers inside the web . The same position being inspected with three different light conditions, enabling reliable conclusions on the defect type and location (top, middle, bottom layer).

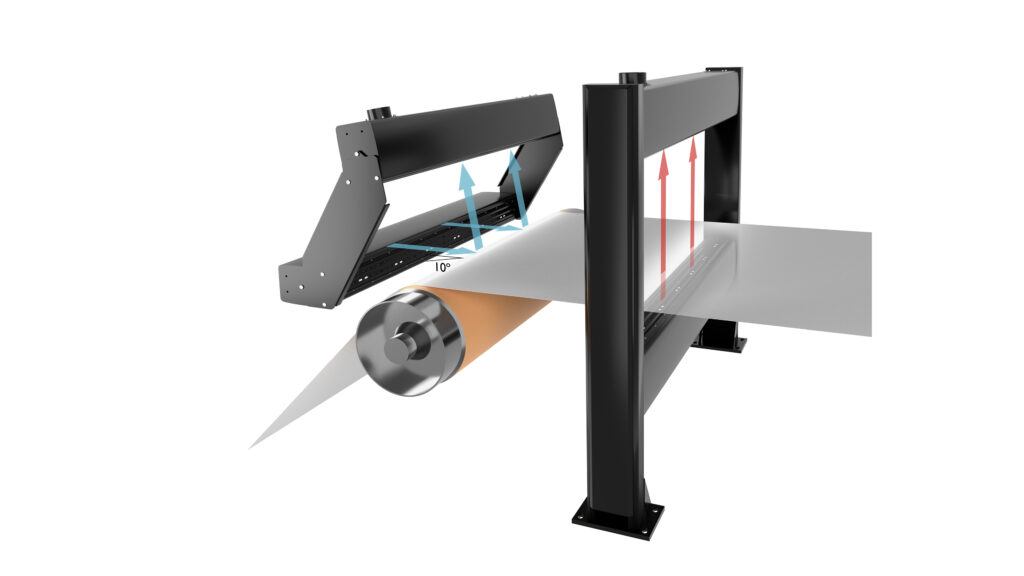

- High-Angle Web Inspection: This geometry is good for detecting reflective and surface-related defects.

- 3D-Detection: Enables detection of topological defects like indents, outdents bumps, backing roll marks, and other surface irregularities.

- Low-Angle Web Inspection: The camera and light source are positioned at a low 15-20 degree angle to the web surface. This geometry excels at detecting faint defects such as coating streaks, wrinkles, coating skips or other defects that are not visible from another angle.

From the bottom side of the web

- 3D-Detection

- High-Angle Web Inspection

- Low-Angle Web Inspection

Deeper Insight Through Geometry Combination

By combining inspection data from different geometries, the system can provide a much richer defect profile. For example, defects seen in both transmission and reflection, but not in 3D, can be classified differently from defects that appear only in 3D or only under UV. This cross-validation enables more accurate and reliable classification, reducing false root cause analysis and improving production efficiency.

Built for Demanding Environments

Procemex Web Monitoring and Inspection systems are engineered to withstand the demanding conditions of board and paper production, including high temperatures and mechanical vibrations. Thermal insulation and vibration-proof carbon fiber frames, ensure reliable long-term performance. In some production lines, web inspection beams can be located in areas exposed to extremely high temperatures, presenting a unique technical challenge. To address this, the camera units can be equipped with additional thermal insulation to maintain stable operation, highlighting the importance of application-specific engineering and the role of our experienced experts in identifying the most suitable solution for each customer’s board machine through close collaboration with the mill.

Unified System, One Interface

All these Web Inspection geometries and Web Monitoring cameras operate within one Procemex OnePlatform system. This integration ensures that data from Web Inspection (WIS) and Web Monitoring (WMS) can be used together, in real time, to understand root causes of quality issues and drive process improvements. Operators benefit from a single user interface where all data is synchronized and easily accessible.

You might also be interested in these

Success Story: Metsä Board Äänekoski

Higher Customer Satisfaction and Line Efficiency with Procemex Web Monitoring and Inspection System

Measurement Geometries

Procemex has developed a variety of measurement geometries for detecting and inspecting different types of paper defects.

ProClean Pinhole Camera

Procemex ProClean Pinhole Cameras stay clean even in the harshest conditions