Frames in Low Angle Web Inspection

Low angle web inspection detects and classifies challenging defects like streaks and backing roll markings in mirror reflection against roll.

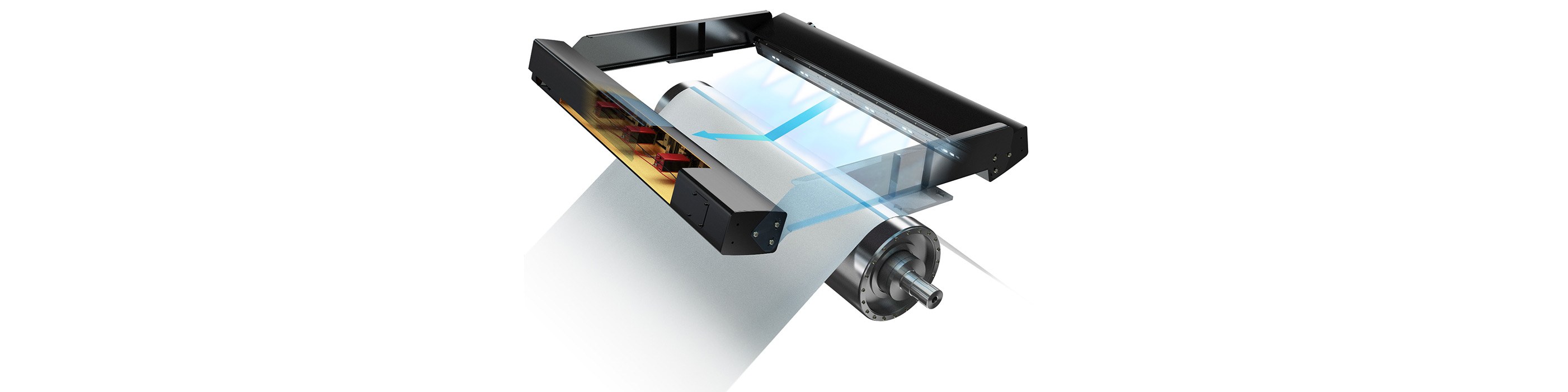

Carbon fiber beams are designed, engineered and constructed specifically for the purpose of absorbing machine induced vibration and are sturdy enough for the widest , over 12 m wide machines in the world. The camera and strobe LED illumination modules are cooled by blown air through the camera and light beams.

Camera and light beams support different inspection geometries starting from simple transmission or reflection measurement extending to complex top and back side multi-illumination measurements.

Some defects may be located in different layers inside the web which requires different illumination for detection. Procemex smart camera controls up to 3 separate strobe light sources simultaneously. The flashing of each light source takes place in individual sequences at the same point of web, resulting in the actual position being inspected 3 times, each under different light conditions. The results of the 3 measurements are combined for reliable conclusions on the defect type and location (top, middle,bottom layer).

Key Features

- Compact smart cameras inside the camera beam

- No electronics cards or power supplies inside the beam

- Smallest size & lightest weight in the market (H270 x W190 mm)

- Eliminates machine-induced vibration

- U-shape camera and light frame give flexibility with moveable camera fixture

- Number of cameras can be increased/decreased inside the camera beam

- One camera frame can use 1-3 light profiles (light frames)

- Light beam movement is not needed

- Smallest size frames in the market– fits easily into tightest locations

- No vibration even with widest frame widths up to 12 meters

- Possibility to add/reduce cameras afterwards

- Multi-illumination solutions possible with strobe light

- Easy service with running machine / no electronics inside beams

- No breaking glass – innovative Teflon foil for LED module protection

- Low heat generation: Camera controlled strobe mode results in low power consumption and respectively in low heat generation

- Strobe illumination enables multi-illumination: Unlike line scan cameras requiring continuous illumination, strobe light together with matrix cameras enable the use of 1-3 separate illumination profiles and even use of different wavelengths

- Compact size and light weight: A preferred solution for existing machines with limited space and easy installation

Specification

- Smallest size in the market (H270mm x W190 mm)

- Weight 20 kg per meter including equipment

- Average LED light power consumption 10 W / meter Average motor cooling air consumption 4- 6m3/min per beam (500 Pa)