3D Web Inspection

3D Web Inspection for Elevated Defects

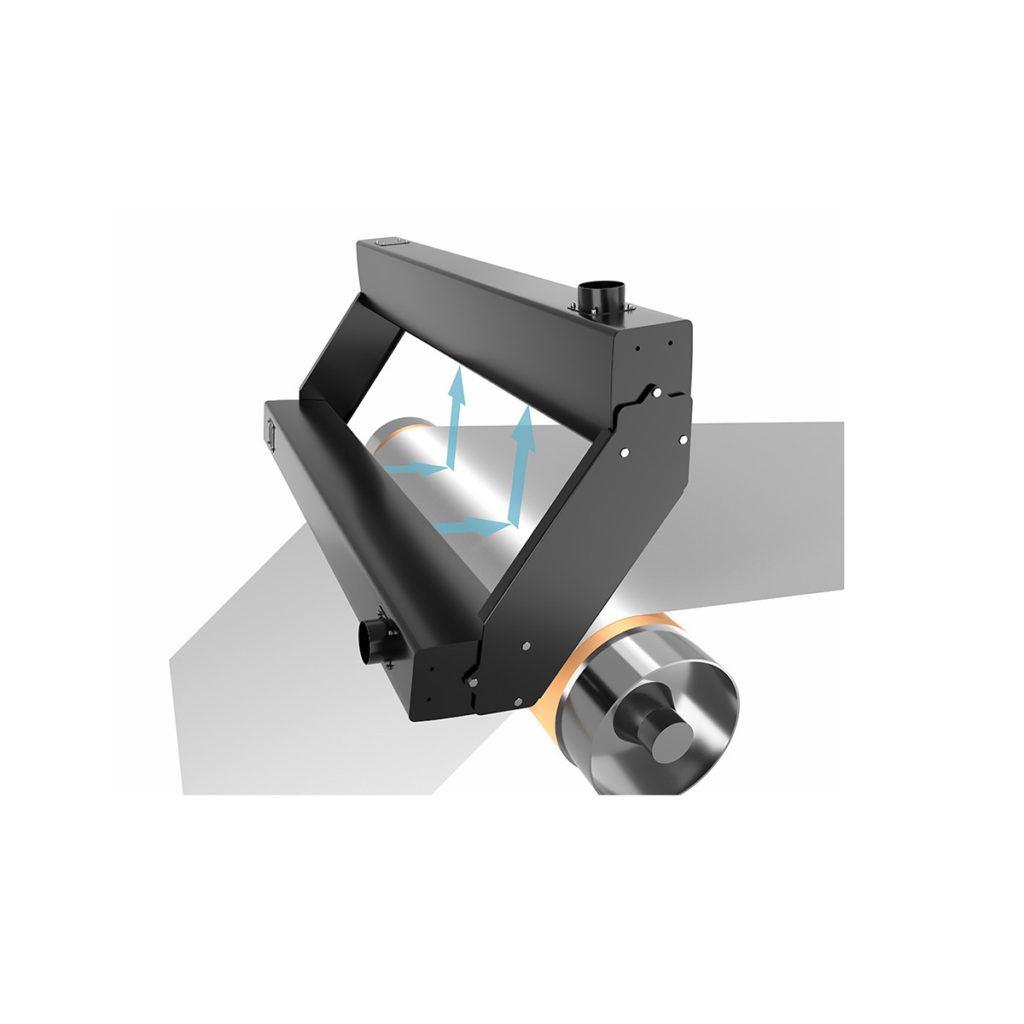

One-profile measurement geometry for detecting and classifying all surface defects keeping focus on dents and elevated defects

The 3D web inspection is performed typically having paper against supporting roll. This geometry enables to detect very small dents and elevated defects in a very high accuracy.

It is based on around 10 degree illumination angle and 90 degree camera viewing angle and can detect all other surface defects on standard paper and board machines.

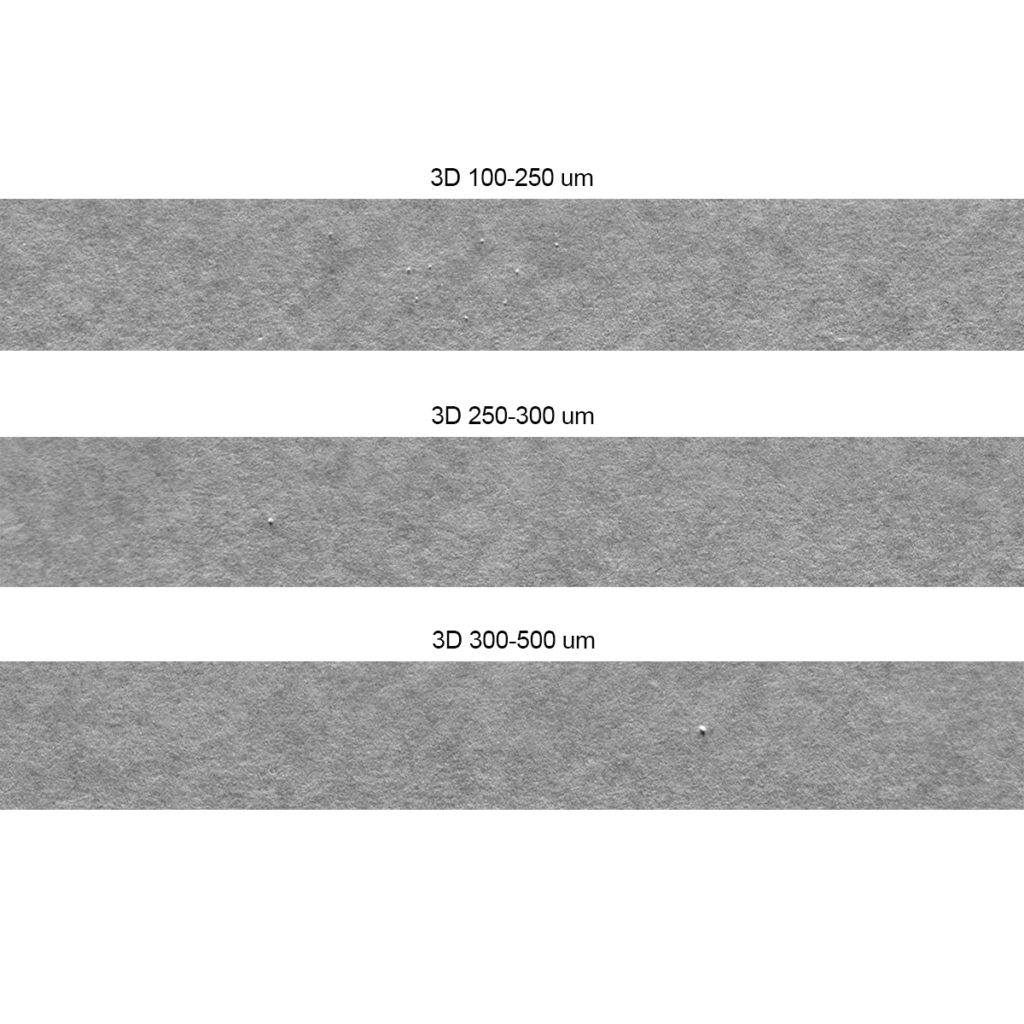

The resolution is typically 0.1×0.1mm requiring above 600 Mhz data processing on a 1000 m/min machine. This enables to detect elevated defects starting from 100 um.

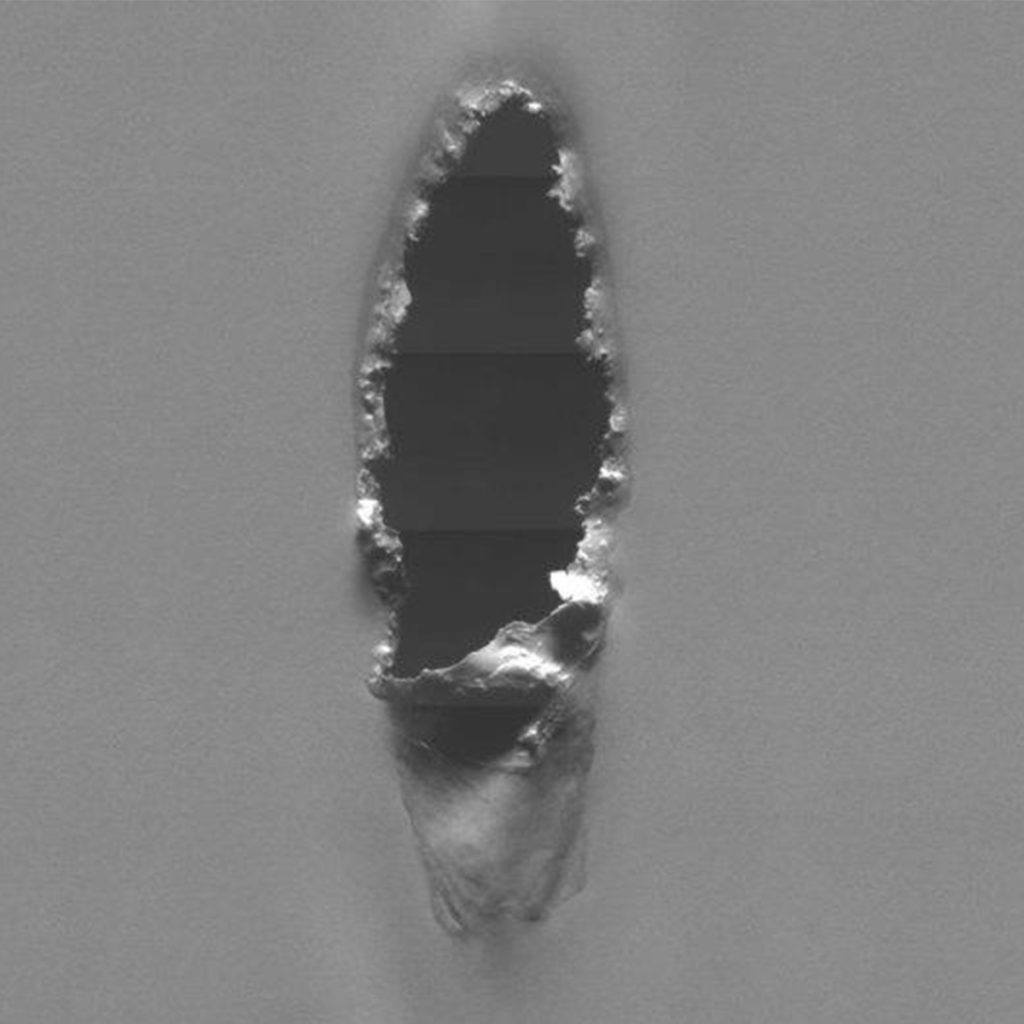

The detection of dents and elevated defects requires a special algorithm developed by Procemex in collaboration with leading Scandinavian liquid packaging board producers.

3D and Transmission Web Inspection

Two-profile measurement geometry for detecting and classifying all surface defects and defects inside product keeping focus on dents and elevated defects.

The 3D web inspection with transmission is performed on free sheet. This geometry enables to detect very small dents and elevated defects in a very high accuracy together with transmitted defects inside the product. It is based on around 10 degree illumination angle and 90 degree camera viewing angle and can detect all other surface defects on standard paper and board machines.

The resolution is typically 0.15×0.15 mm requiring above 600 MHz data processing on a 1000 m/min machine. This enables to detect elevated defects starting from 100 um. The detection of dents and elevated defects requires a special algorithm developed by Procemex in collaboration with leading Scandinavian liquid packaging board producers.